Introducing, the BOEEP’s Stainless Steel Treatment Plant Waste Heat Sludge Low Temperature Belt Dryer - the greatest solution for drying commercial sludge. This was created to run at low conditions to guard the properties where the sludge is being dried up while making certain that it could be properly and effortlessly removed.

The BOEEP’s Stainless Steel Treatment Plant Waste Heat Sludge Low Temperature Belt Dryer was made of top-notch stainless steel that ensure durability and longevity. The employment of stainless additionally means that the item is resistant to corrosion that makes it well suited for use within waste water treatment plants.

One of the top features of the BOEEP’s Stainless Steel Treatment Plant Waste Heat Sludge Low Temperature Belt Dryer is its power to run using waste, making it an eco-friendly selection. The dryer was made to extract waste temperature from current commercial procedures, making it an economical answer for organizations wanting to reduce their power usage.

This was designed for dealing with commercial sludge that needs to be dried out before disposal. The sludge is transported through the low-temperature belt drying equipment, which guarantees a straight circulation of temperature to stop any burned or damaged sludge that could otherwise never be appropriate for disposal.

BOEEP's Stainless Steel Treatment Plant Waste Heat Sludge Low Temperature Belt Dryer dries sludge while creating minimal temperature. The dryer has an automated, which helps to make sure that the drying heat is stable and constant through the drying process. The high-precision temperature and moisture sensors assist carry on with the drying conditions that is perfect for the sludge.

Among the list of top features of the BOEEP’s Stainless Steel Treatment Plant Waste Heat Sludge Low Temperature Belt Dryer is that it decreases the extra weight of sludge. It will help to ensure that less waste is produced and the rest of the waste is safer to manage and get rid of in an environmentally accountable way

BOEEP's Stainless Steel Treatment Plant Waste Heat Sludge Low Temperature Belt Dryer is an extremely efficient and effective solution in drying commercial sludge. It was built to be economical, zero-maintenance and durable, making it a fantastic option for organizations and wastewater treatment plants searching for a dependable and eco-friendly option to sludge disposal

Waste Heat Sludge Low Temperature Belt Dryer

Products Description

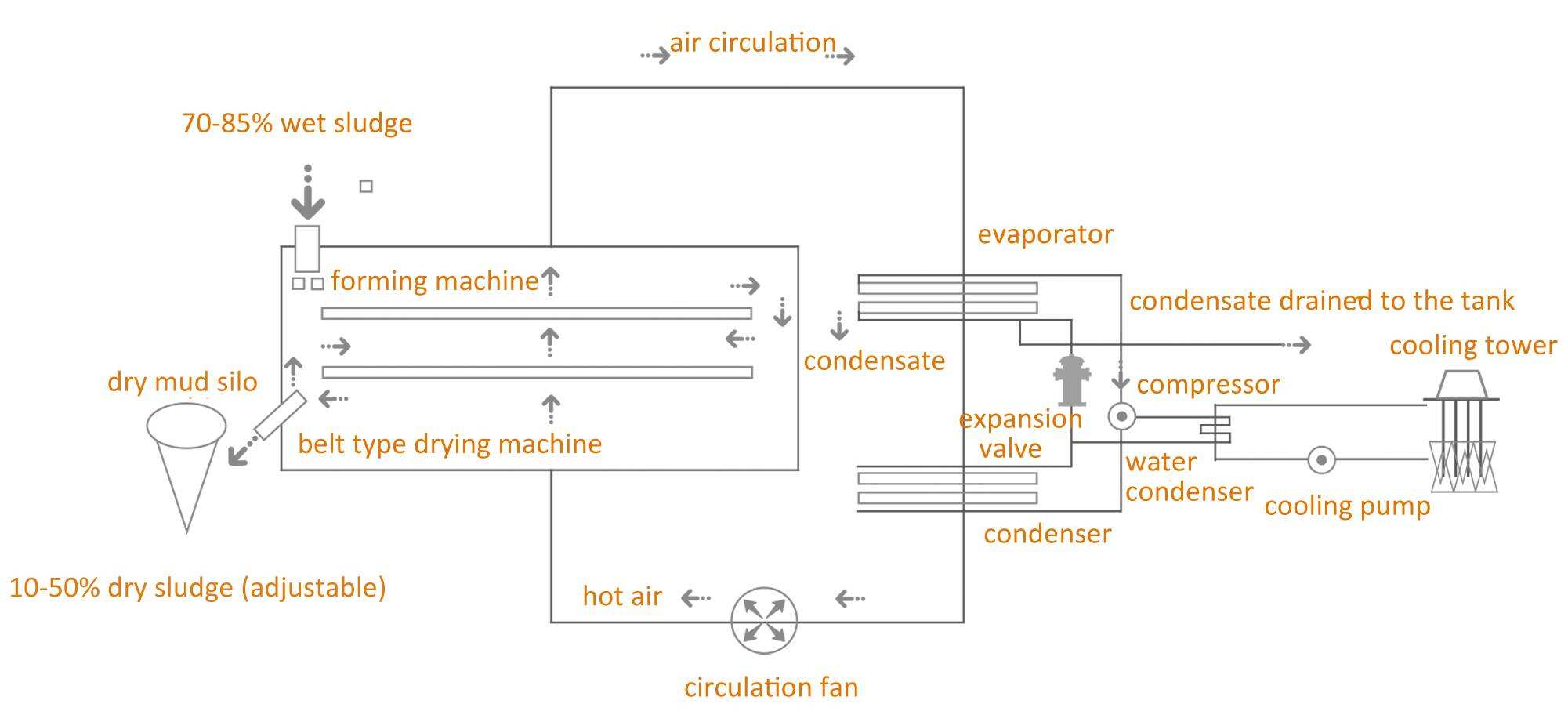

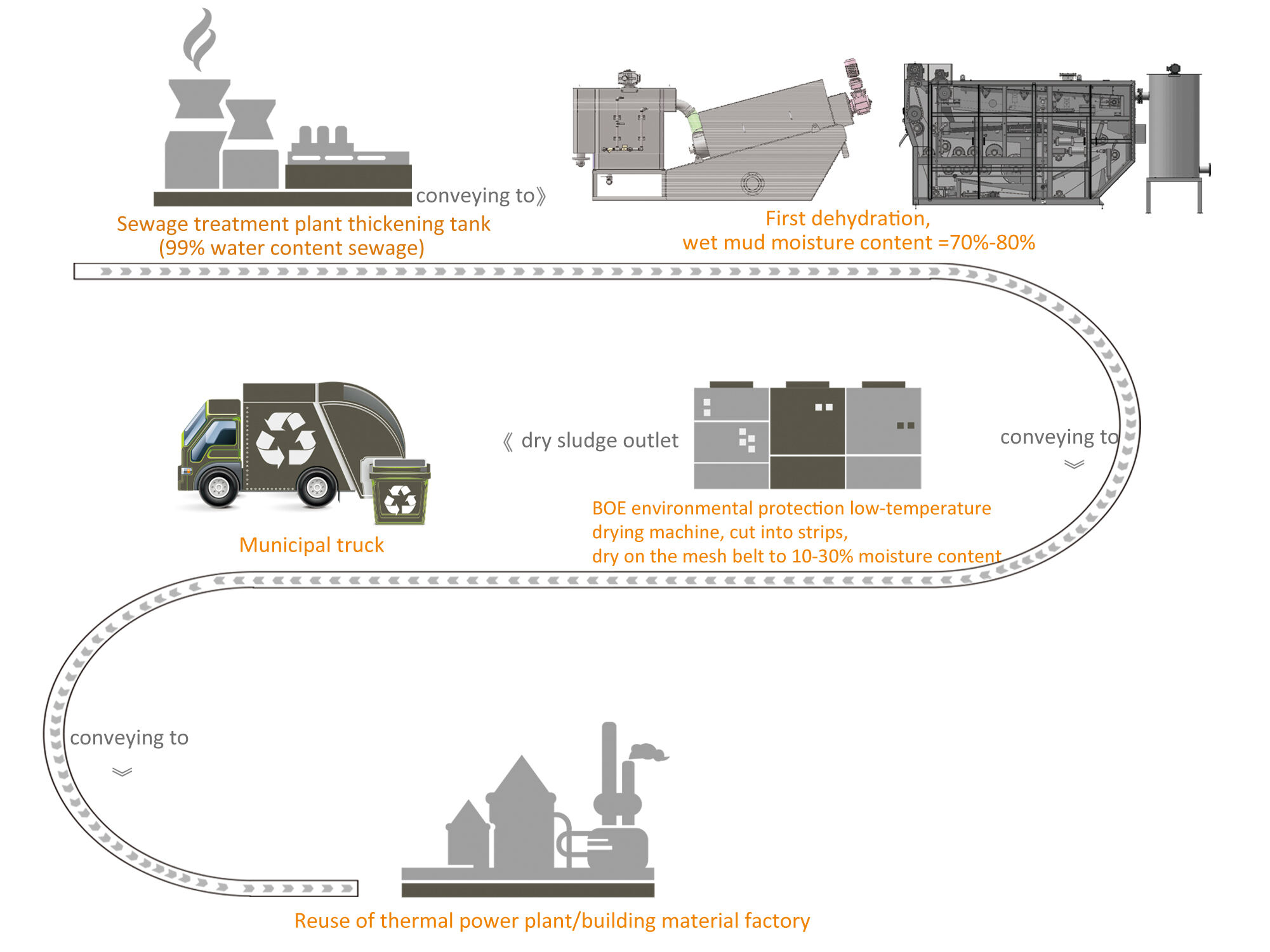

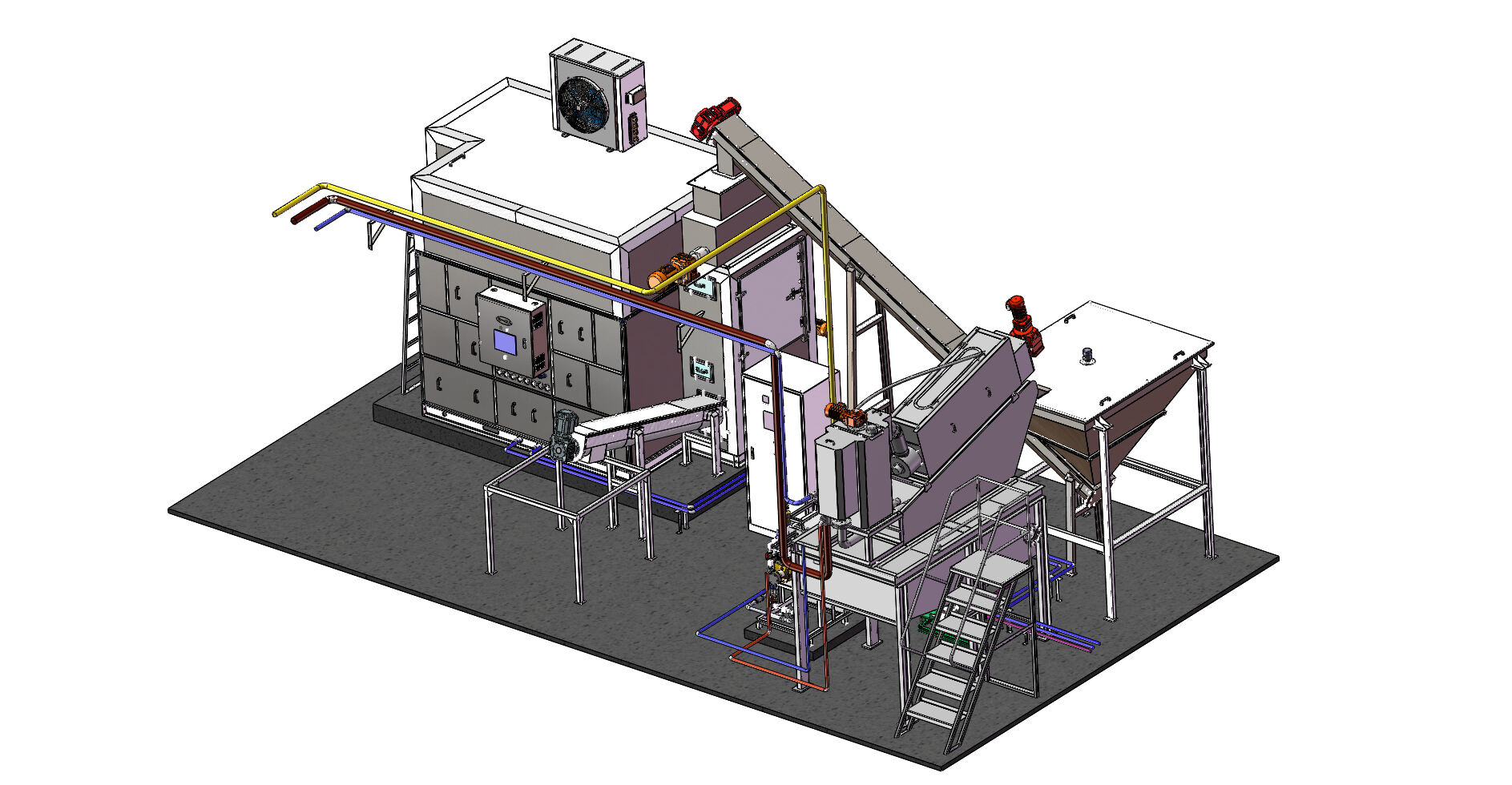

The low-temperature sludge drying equipment developed by BOE environmental Protection can directly dry sewage or sludge with a moisture content of less than 83% to dry sludge with a moisture content of 10%-30%. The reduction can be as high as 90%, and the effective sterilization can be as high as 90%. Low energy consumption, no pollution, widely used in municipal sludge and industrial sludge (printing and dyeing, papermaking, electroplating, chemical industry, leather, pharmacy, etc.) for drying reduction. Dry sludge with 10%-30% moisture content can be gasified later, Mixed burning, composting, or building materials and other harmless resource disposal Low temperature drying principle

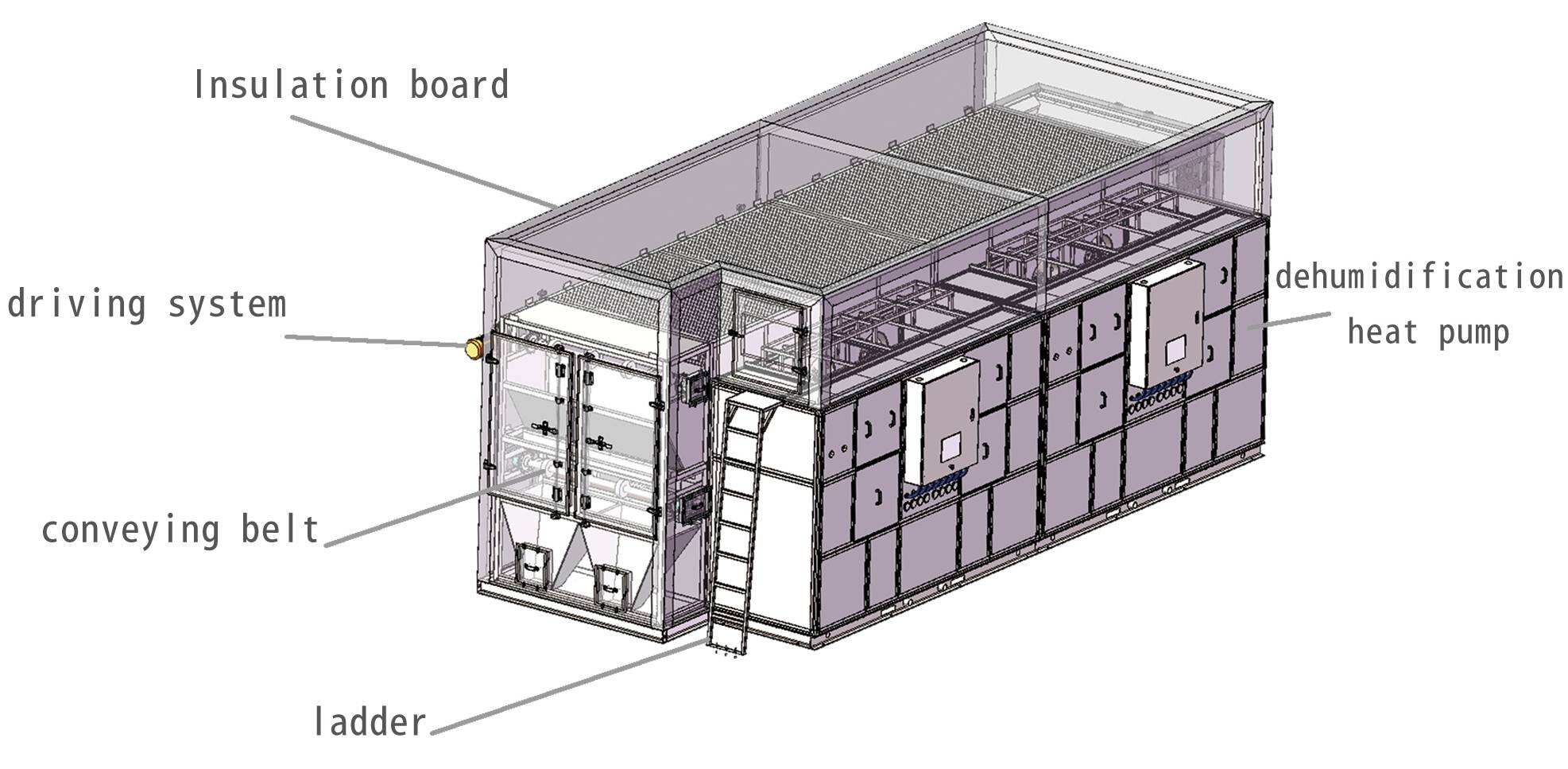

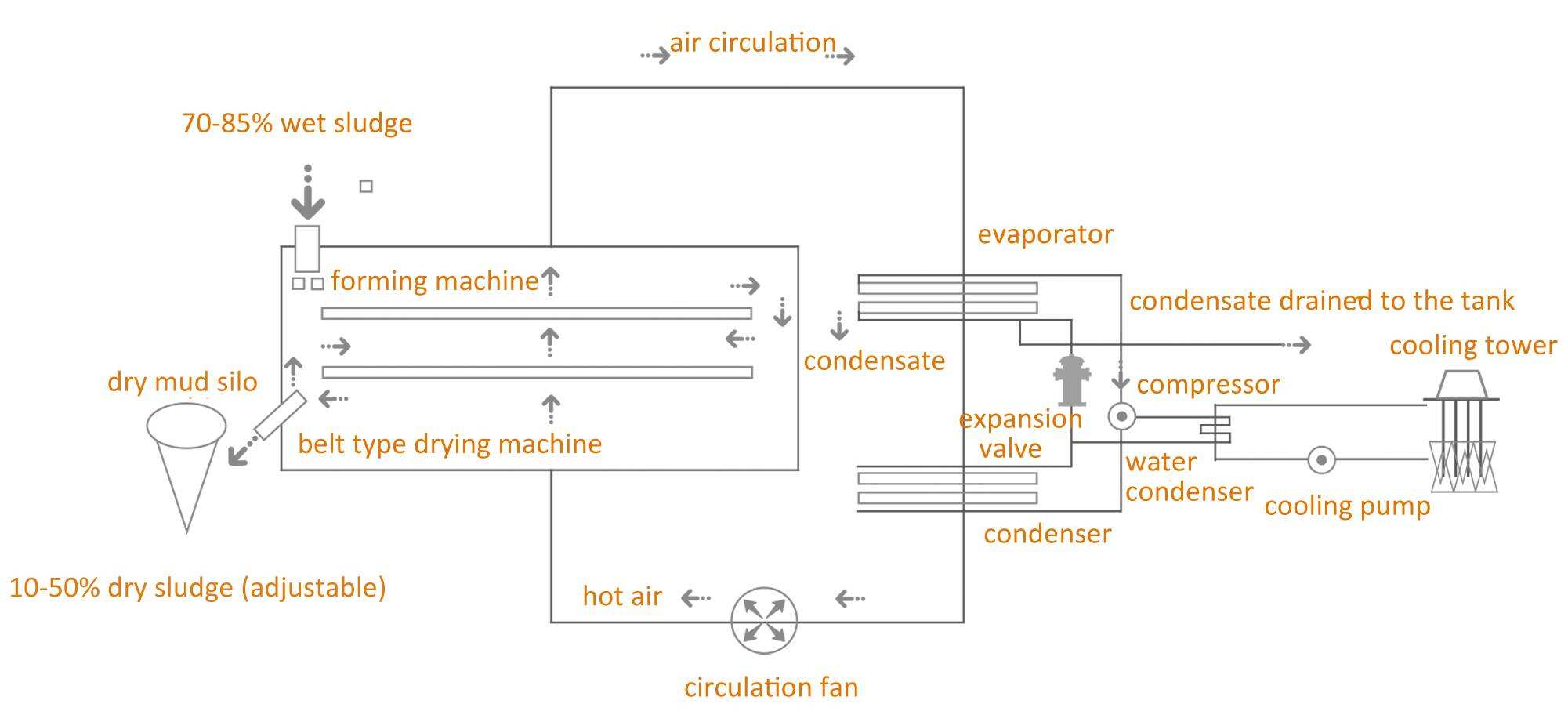

Low temperature drying principle The low-temperature sludge drying equipment independently developed by BOE Environmental Protection uses the principle of low-temperature heat pump dehumidification and uses convection hot air drying to reduce the amount of wet sludge on the mesh belt. The whole set is the same as a fully enclosed type. Design, dry hot air without heat loss

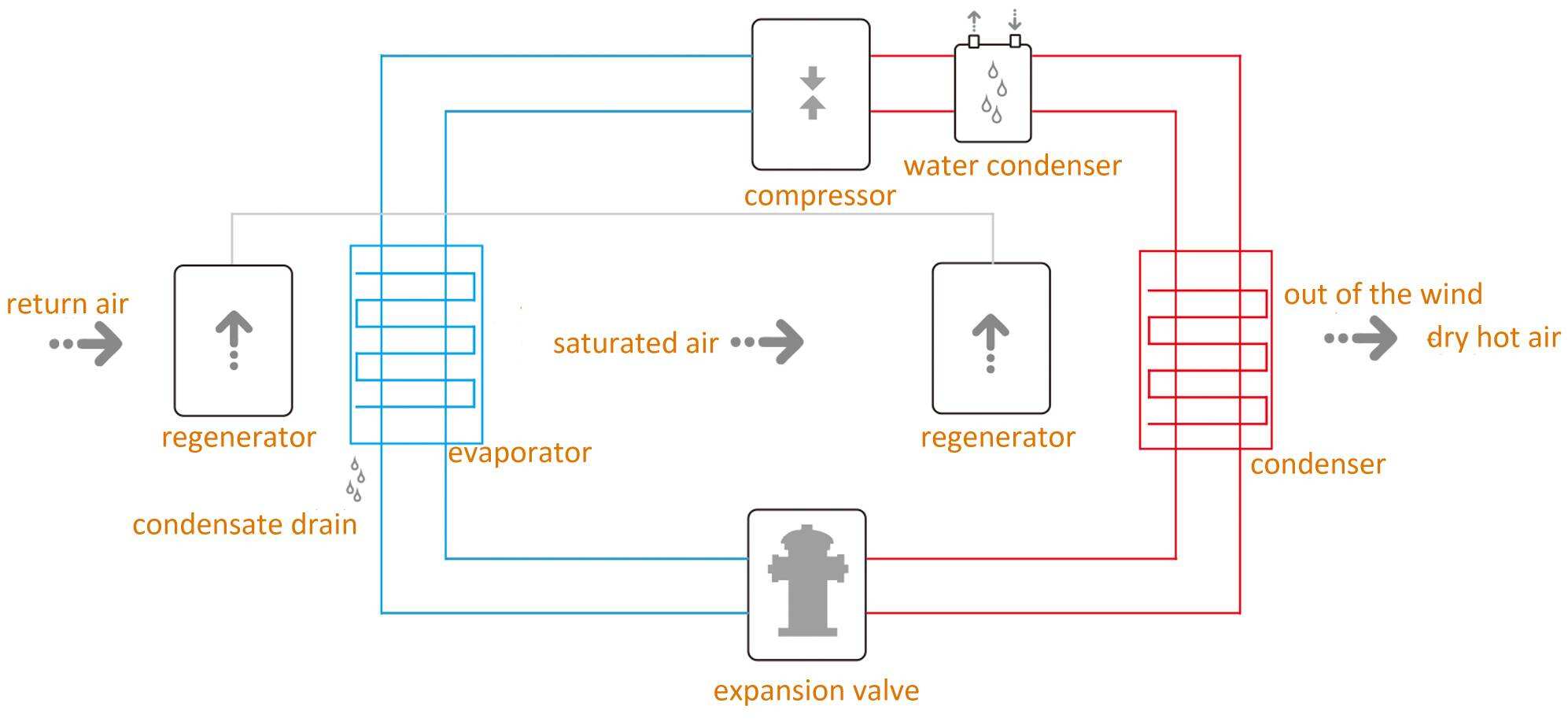

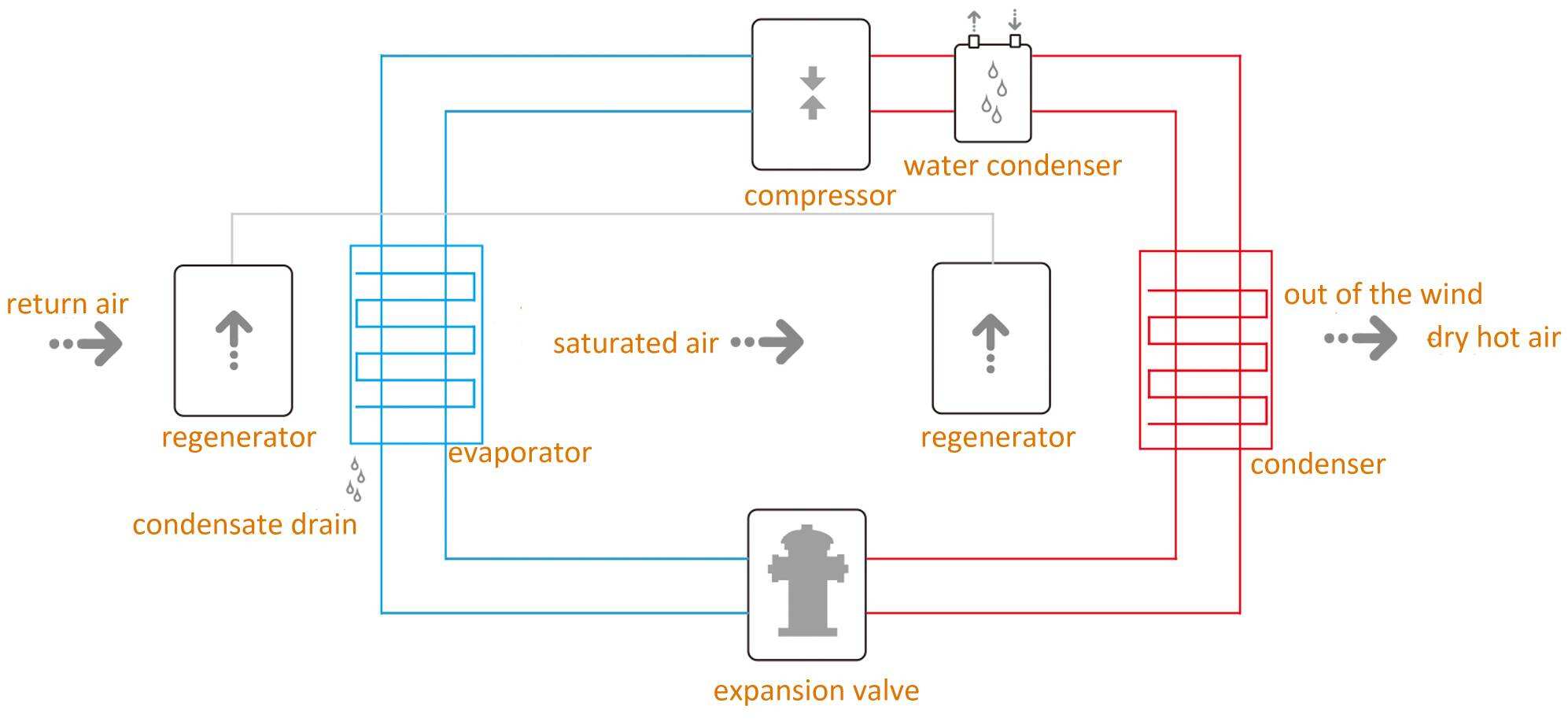

Dehumidification heat pump principle

The refrigeration system is used to cool and de-humidify the humid air from the drying room, and at the same time recover the latent heat of moisture condensation to reheat the dry air. It is a combination of dehumidification (dehumidification and drying) and heat pump (energy recovery), and is the recycling of energy in the drying process

Innovative Technology

Four-effect technology, twice the industry standard

Four-effect condensation dehumidification drying technology is an advanced sludge drying reduction technology. It has significant advantages such as lower air outlet temperature, better drying capacity and efficiency, and more economical operating costs; adopts "four-effect condensation dehumidification and drying" equipment, and the comprehensive dehumidification performance ratio (SMER) is as high as 4kg. H2O/kw. h or more, The moisture content of dry mud is reduced to 10%-30%, which is more than 50% energy-saving than traditional low-temperature drying, which is twice the industry standard

A variety of molding technologies, comprehensive energy efficiency leading 40%

Based on years of successful experience, different types of wet mud, and different moisture content, different molding technologies are used to reduce the drying time of wet mud, and the comprehensive energy efficiency is 40% ahead of the industry

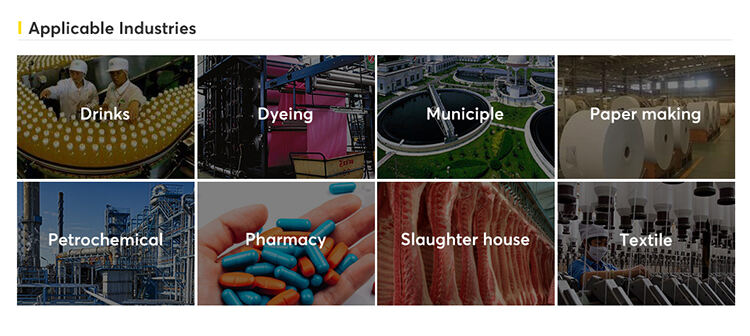

Wide range of applications

1. It can be widely used in the drying treatment of various types of sludge in municipal administration, printing and dyeing, papermaking, electroplating, chemical industry, leather, etc.;

2. The daily dehumidification and water removal capacity of a single device ranges from 200 kg to 50 tons, and all models can meet;

3. Electric energy can be used directly, or energy such as steam and waste heat can be used;

4. It can be “centralized treatment” or “decentralized treatment” to meet the requirements of sludge disposal policies in different regions;

5. It is not affected by the external environment temperature (low temperature in winter) and humidity (humidity in summer), suitable for use in various regions;

Safe and harmless

1. Fully-enclosed low-temperature operation at 40-75℃, no nitrogen filling operation required;

2. During the drying process, the oxygen content is less than 12%, the dust concentration is less than 60g/m3, the particle temperature is less than 70℃, and there is no danger of dust and explosion;

3. The sludge is statically spread, and there is no mechanical electrostatic friction with the contact surface;

4. There is no "sticky phase" stage of the urban sludge drying process (about 60%);

5. The dry material is in granular form and there is no danger of dust;

6. The discharging temperature is low (<50℃), no="" cooling="" is="" needed="">

High efficiency reduction

1. It can directly dry the sludge with a moisture content of 83% to 10% without disposing in stages;

2. There is no loss of organic components in the drying process, and the dry material has a high calorific value, which is suitable for later resource utilization;

3. The reduction can be as high as 80%, which can save a lot of later transportation costs; 4. Using Pasteur (pasteurization) sterilization method-low temperature heat sterilization, the drying temperature is above 70 ℃ for 90 minutes to 120 minutes, and the effective sterilization is as high as 90%;

Skills design

1. Adopt heat pump heat recovery technology, closed drying mode without any waste heat emission;

2. 80% wet mud is dried to 60% per ton, and the comprehensive power consumption is 125kw/h;

3. 80% wet mud is dried to 10% per ton, and the comprehensive power consumption is 200kw/h;

4. 4 kg of water can be removed per 1 kilowatt-hour of electricity (the dehumidification performance ratio is 1:4kg. H2o/kw/h);

Environmentally friendly and odorless

1. The entire equipment system adopts a closed design, no odor overflows, and no complicated deodorizing device is required;

2. Using low temperature drying process, the amount of H2S and NH3 precipitation is greatly reduced;

3. Condensate (sludge moisture) is easy to dispose of and can be discharged directly;

4. Adapt to sewage plants in urban areas, villages and scenic spots;

Economic savings

1. It occupies a small area, with an average treatment area of about 4m2 per ton of wet mud;

2. It can be installed in the basement to save land area;

3. No complicated civil structures and infrastructure, saving civil construction costs;

4. The equipment is simple to install, and the installation and debugging cycle is short, saving time and cost;

Smart operation

1. The equipment runs fully automatically, saving a lot of labor costs;

2. "PLC+touch screen" intelligent control can realize remote centralized control;

3. The moisture content of the discharge material can be adjusted arbitrarily (10%-50%);

Stable and durable

1. The use of corrosion-resistant materials such as stainless steel, and the heat exchanger with electroplating anti-corrosion treatment, have a long service life;

2. There is no mechanical wear during operation, and the service life is more than 15 years;

3. No vulnerable and consumable parts, easy to use and manage;

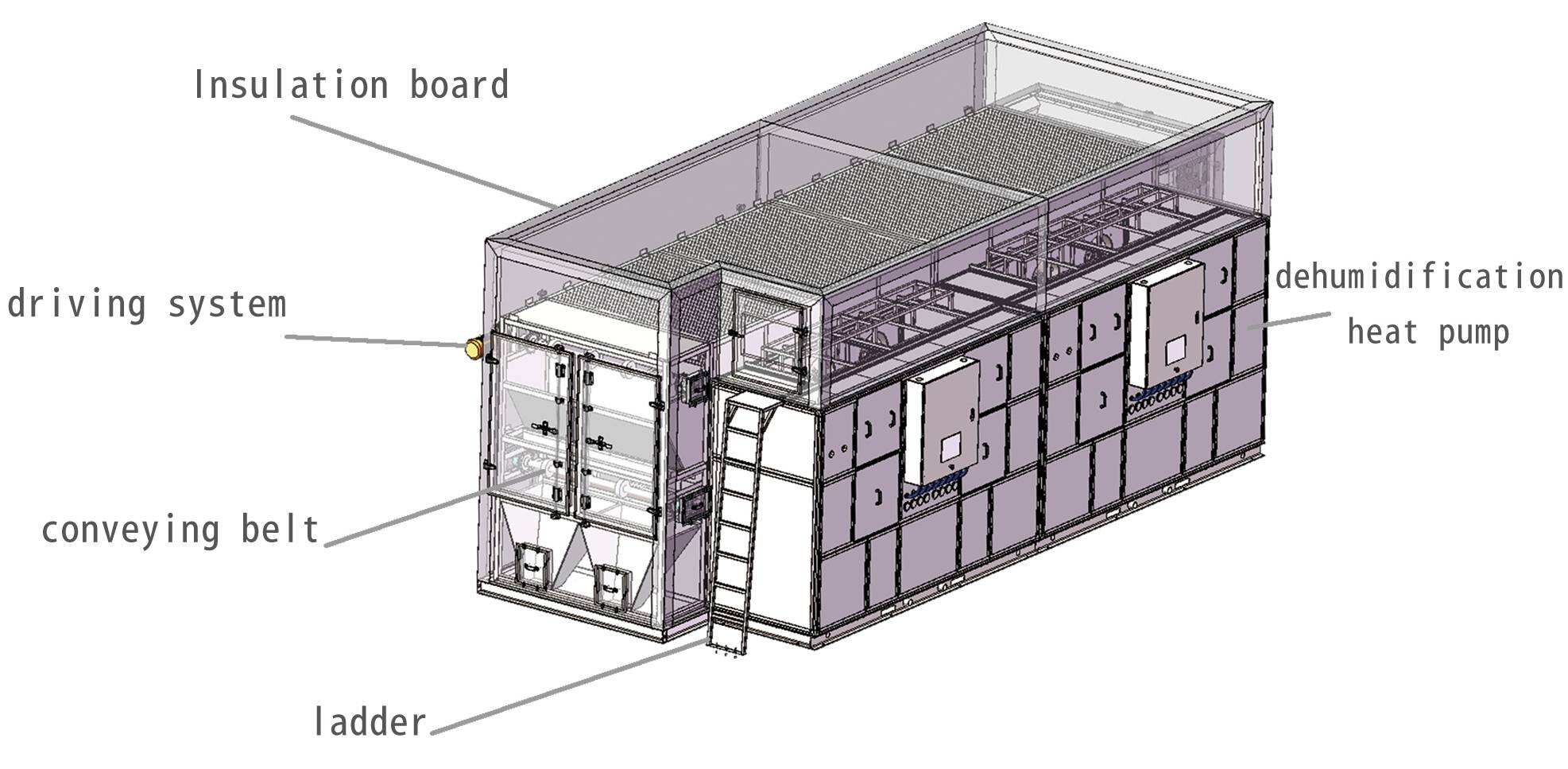

Sludge low temperature belt dryer

Features

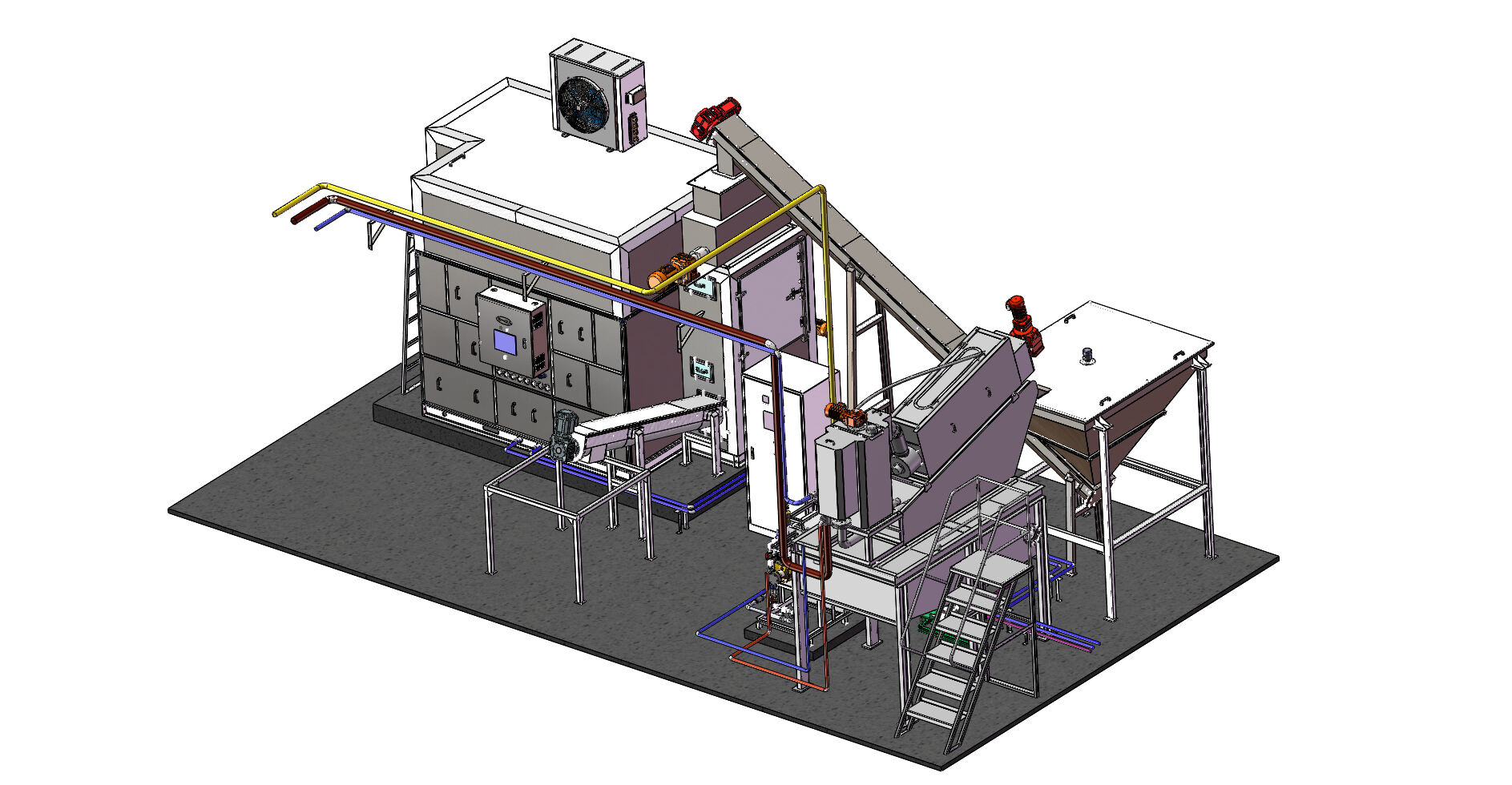

1. Integrated modular design

The sealing of the air duct is improved by the integrated configuration of drying chamber and the waste heat exchange module. Product modular design and production; modular assembly and transportation; fast installation at site

2. The heat sources such as steam, smoke and waste heat oil can be converted into hot water for use. The steam can also be directly used for heat exchanging, which shortens the heat exchange process and improves the efficiency

3. Stainless steel 316L evaporator and condenser tube design

The circulating water tube is made of stainless steel 316L, which is more resistant to corrosion

4. The material of the whole equipment is corrosion -resistant stainless steel, which is resistant to corrosive sludge condition. The parts and components in contact with the sludge are equipped with stainless steel 304 as standard. Stainless steel 316L can be used according to site conditions and customer requirements

5. The heat exchange system is upgraded: the heat exchange and dehumidification performance is increased by more than 15%

6. Internet of Things platform technology

The key running parameters and real -time running status can be transmitted to mobile phones and computer terminals at any time by the Internet of Things to realize the equipment remote monitor and status adjustment

7. Automatic dust removal and air lock design

(1) Some products can be designed with automatic dust removal as an optional, which improves the filtration and reduces labor costs

(2) A variety of air locking proposals are used to guarantee the material discharge without any air leakage and minimize the overflow of dust and odor

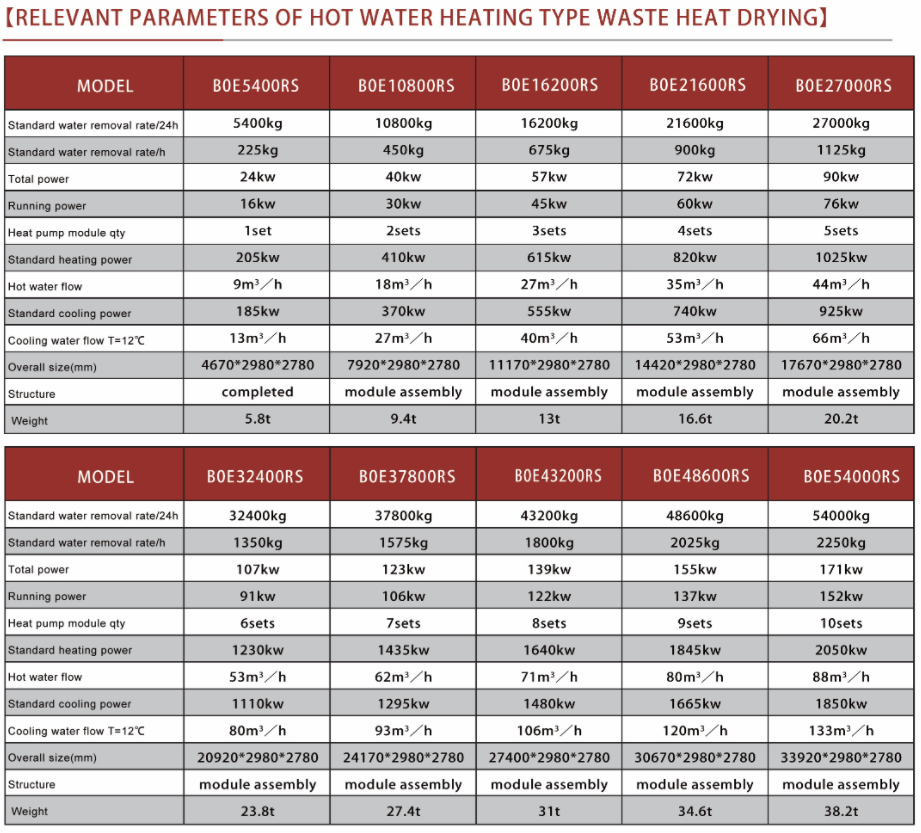

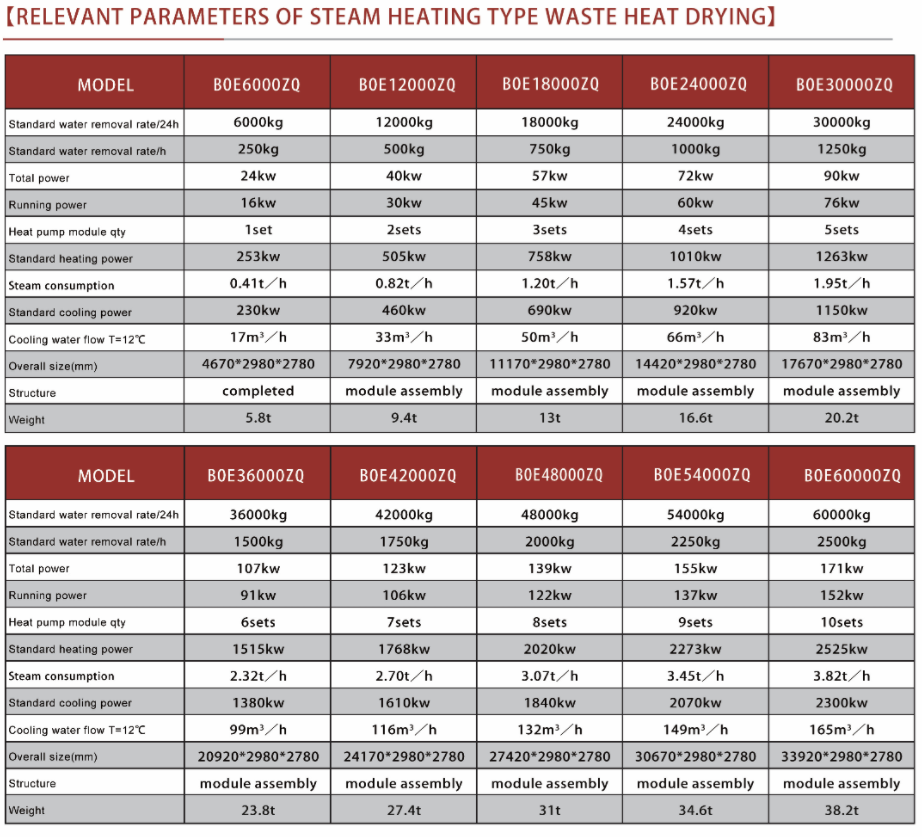

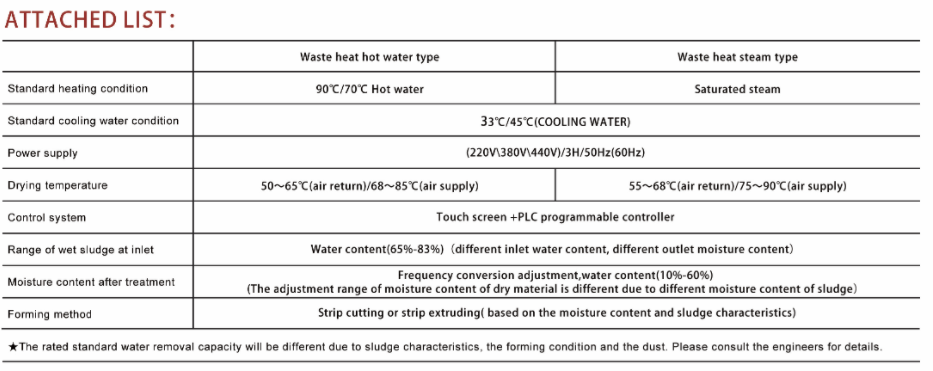

Specification

About Us

Q: Are you trading company or manufacture

A: We are both manufacture and trading company. We have over 20 years' professional experience as a waste water treatment equipment manufacturer and engineering service enterprise

Q: Where is your factory located

A: Yangzhou City, which is very close to Shanghai with only less than 3 hours' driving

Q: Do you provide OEM service

A: Yes. Any required logos is available

Q: How about the production capacity of your company

A: Our factory covers area over 20,000M2 and produces machines 2000 sets per year

Q: How could we trust you and your company? This is first time transaction

A: Our company has more than 20 years professional experience. We cooperate over 1000 customers in China and overseas. We export nearly 40 countries all over the world. Welcome to our company and watch our plant production condition any time

Q: What certificates do you have

A: CE/ISO/SGS

Q: Do you offer after-sales service

A: Yes. Engineers available

Q: How long is your warranty

A: One year after the arrival of the goods. During this period, as long as it is not a man-made damage, we send the damaged parts free of charge

Q: What about your delivery time

A: Normally within 45 days against down payment

Q: What about the package of your export product

A: We use anti-corrosion wooden case with foam inside

Q: What kind of payment do you accept

A: T/T, L/C, PAYPAL, Cash, D/P, D/A, WESTERN UNIION, MONEYGRAM

Q: What kind of transportation do you offer

A: Customers decide freight mode, Air, Land & Sea