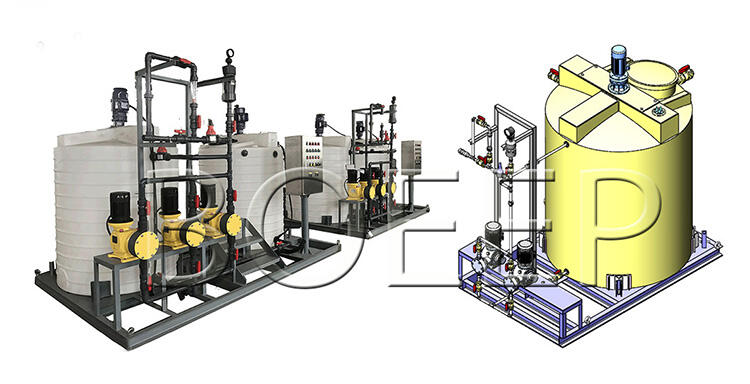

Introducing, the BOEEP’s industrial manual ingredients dosing machine system! This top-quality dosing is ideal for including accurate amount of chemical powder and liquid Flocculator into waste water treatment procedures.

Created from durable materials, the BOEEP’s dosing machine was made to withstand the needs of commercial applications. The pump was made to manage chemical powders and fluids with simplicity, making sure the right amount is constantly put in the treatment procedure. This dosing system is great for large-scale treatment plants that need to process high volumes of waste water, featuring its big ability.

One of the top features of the BOEEP’s dosing machine is its manual dosing settings. This permits operators to fine-tune the exact quantities, making the procedure optimized for optimum effectiveness. Plus, the settings are simple to use, so there's no need for considerable training or complicated working procedures.

Another benefit of BOEEP’s dosing system is its liquid Flocculator. This effective Flocculator keeps suspended particles to the wastewater, making it more simp;le to process and treat. And because it is included in the dosing system, there is no need to buy a separate computer device, saving operators time and money.

When it comes to installation, the BOEEP’s dosing system is simple and easy to produce. With its compact design, it won’t occupy too much area to your waste water treatment center. Plus, the low-maintenance design helps to ensure that you'll save money and time on repairs and upkeep.

The BOEEP’s industrial manual ingredients dosing machine system is a top-of-the-line dosing solution for waste water treatment facilities. Its durable construction, accurate dosing settings, and effective Flocculator makes it an ideal option for commercial applications. Along with its simple installation and design, it is a sensible investment to any waste water treatment plant

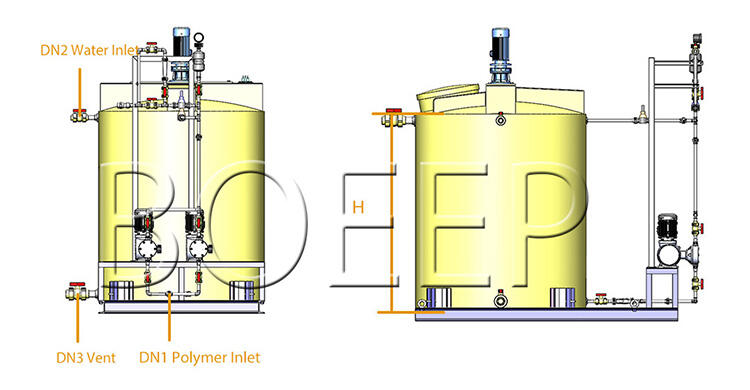

Model |

Moninal volume - m³ |

Mixing power |

Barrel diameter - mm |

Barrel height H - mm |

Polymer outlet DN1 - mm |

Water inlet DN2 - mm |

Drain DN3 - mm |

DJY1000 |

1.0 |

0.55 |

1000 |

1300 |

25 |

25 |

32 |

DJY2000 |

2.0 |

1.1 |

1300 |

1650 |

25 |

25 |

40 |

DJY3000 |

3.0 |

1.5 |

1600 |

1600 |

25 |

25 |

40 |

Q: Are you trading company or manufacture

A: We are both manufacture and trading company. We have over 20 years' professional experience as a waste water treatment equipment manufacturer and engineering service enterprise

Q: Where is your factory located

A: Yangzhou City, which is very close to Shanghai with only less than 3 hours' driving

Q: Do you provide OEM service

A: Yes. Any required logos is available

Q: How about the production capacity of your company

A: Our factory covers area over 20,000M2 and produces machines 2000 sets per year

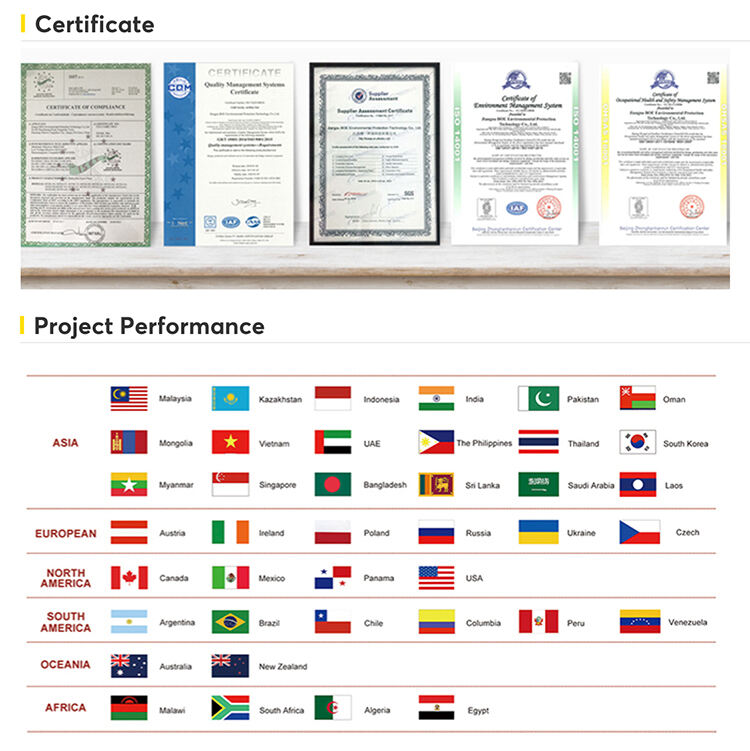

Q: How could we trust you and your company? This is first time transaction

A: Our company has more than 20 years professional experience. We cooperate over 1000 customers in China and overseas. We export nearly 40 countries all over the world. Welcome to our company and watch our plant production condition any time

Q: What certificates do you have

A: CE/ISO/SGS

Q: Do you offer after-sales service

A: Yes. Engineers available

Q: How long is your warranty

A: One year after the arrival of the goods. During this period, as long as it is not a man-made damage, we send the damaged parts free of charge

Q: What about your delivery time

A: Normally within 45 days against down payment

Q: What about the package of your export product

A: We use anti-corrosion wooden case with foam inside

Q: What kind of payment do you accept

A: T/T, L/C, PAYPAL, Cash, D/P, D/A, WESTERN UNIION, MONEYGRAM

Q: What kind of transportation do you offer

A: Customers decide freight mode, Air, Land & Sea