BOEEP is a respected maker of automated SS304 316 sludge treatment procedure thickening de-watering rotary drum belt filter press equipment manufacturers. This innovative technique was built to change the way companies handle sludge treatment, making the procedure more effective and economical.

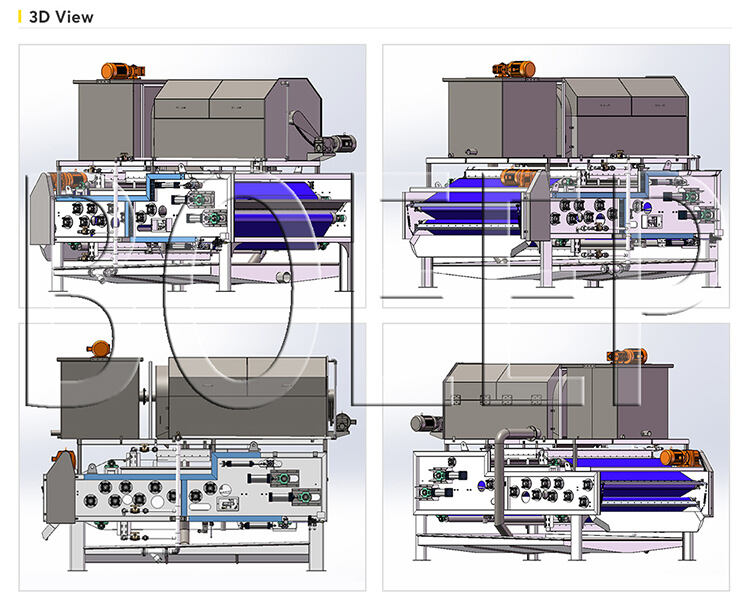

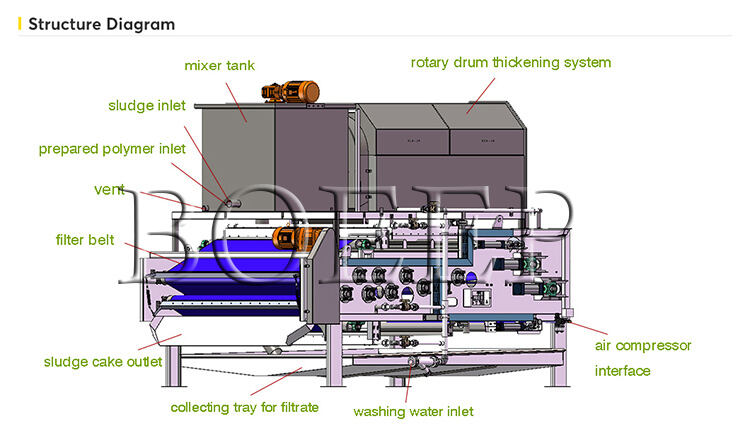

This equipment was constructed of top-quality stainless steel that is durable, efficient and resistant to corrosion. The rotary drum belt filter press has a regular feeding and discharging system, enabling the sludge become prepared. The compact style of the equipment makes it simple to place in and run, also in restricted areas.

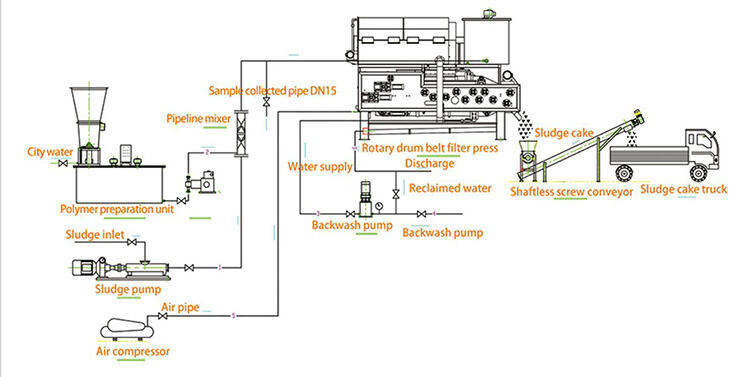

The aautomated SS304 316 sludge treatment procedure thickening de-watering rotary drum belt filter press equipment manufacturers was built to manage many sludge kinds, including commercial sludge, municipal sludge, and chemical sludge. This has the capability of attaining sludge and dewatering outcomes, which reduce the level of sludge to be removed, making the apparatus more eco-friendly.

This also includes an automatic cleansing that guarantees the filter fabric continues to be clean through the entire procedure, prolonging its lifespan and reducing upkeep expenses. The apparatus is full with security system that guarantees the apparatus runs pollution-free and properly.

This has low energy usage and high effectiveness, that will help to make sure that the apparatus runs at an affordable and creates top-quality outcomes. The apparatus includes a user-friendly screen that permits operators to effortlessly set and adjust the processing parameters to optimize the task.

BOEEP's automated SS304 316 sludge treatment procedure thickening de-watering rotary drum belt filter press equipment manufacturers is wonderful for lots of companies, including food processing, petrochemicals, sludge treatment plants, and waste water treatment plants. The apparatus guarantees the sludge treatment procedure is efficient, safe, and green.

If you are finding a top-notch, efficient, and dependable sludge for your equipment, BOEEP's automated SS304 316 sludge treatment procedure thickening de-watering rotary drum belt filter press equipment manufacturers is the right choice. This equipment guarantees a clean and sustainable future for your needs, featuring its advanced features, user-friendly program, and low-to-zero maintenance expenses. Contact BOEEP today for more information about the item and exactly how it can help your company

Model |

ZDY1.0 |

ZDY1.5 |

ZDY2.0 |

Remark |

|||

Belt width - mm |

1000 |

1500 |

2000 |

||||

Capacity(m3/h), inlet concentration - S.S. 1~5 |

5-10 |

8-15 |

12-20 |

Depending on the characteristic of sludge |

|||

Sludge cake moisture content - % |

75-85 |

75-85 |

75-85 |

||||

Motor powe - kw |

Driving motor(frequency control) |

0.37 |

0.75 |

0.75 |

|||

Drum thickening motor, frequency control |

0.37 |

0.55 |

0.55 |

||||

Agitator motor |

0.37 |

0.55 |

0.55 |

||||

Lower collecting tray for filtrate |

YES |

YES |

NO |

||||

External dimension - mm |

L |

2600 |

3220 |

3400 |

Please ask for the actual installation size drawing before purchasing |

||

W |

1550 |

2130 |

2750 |

||||

H |

2540 |

2360 |

3105 |

||||

Base dimension L1*L2 - mm |

2100*1300 |

2440*1720 |

2715*2420 |

||||

Reference weight - kg |

1100 |

1650 |

2920 |

||||

Q: Are you trading company or manufacture

A: We are both manufacture and trading company. We have over 20 years' professional experience as a waste water treatment equipment manufacturer and engineering service enterprise

Q: Where is your factory located

A: Yangzhou City, which is very close to Shanghai with only less than 3 hours' driving

Q: Do you provide OEM service

A: Yes. Any required logos is available

Q: How about the production capacity of your company

A: Our factory covers area over 20,000M2 and produces machines 2000 sets per year

Q: How could we trust you and your company? This is first time transaction

A: Our company has more than 20 years professional experience. We cooperate over 1000 customers in China and overseas. We export nearly 40 countries all over the world. Welcome to our company and watch our plant production condition any time

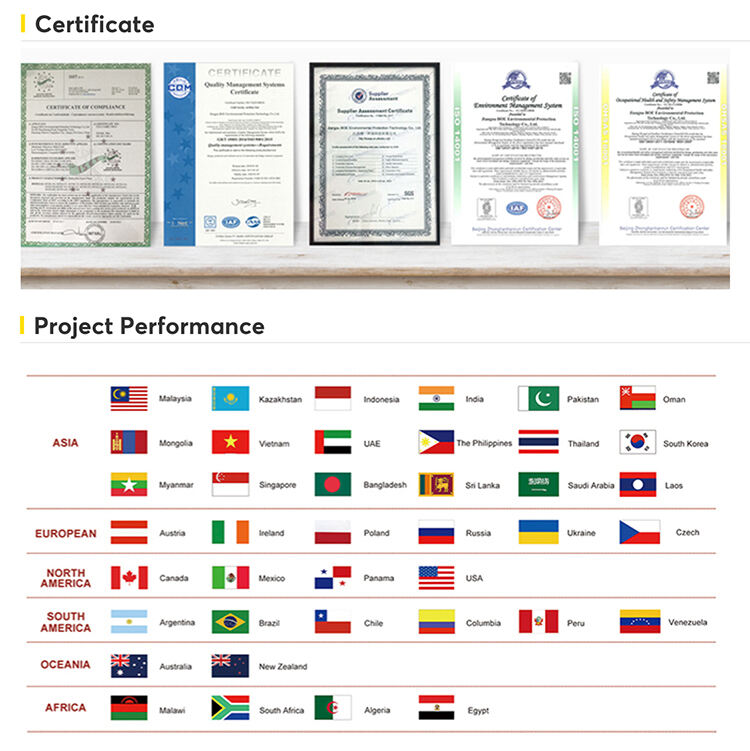

Q: What certificates do you have

A: CE/ISO/SGS

Q: Do you offer after-sales service

A: Yes. Engineers available

Q: How long is your warranty

A: One year after the arrival of the goods. During this period, as long as it is not a man-made damage, we send the damaged parts free of charge

Q: What about your delivery time

A: Normally within 45 days against down payment

Q: What about the package of your export product

A: We use anti-corrosion wooden case with foam inside

Q: What kind of payment do you accept

A: T/T, L/C, PAYPAL, Cash, D/P, D/A, WESTERN UNIION, MONEYGRAM

Q: What kind of transportation do you offer

A: Customers decide freight mode, Air, Land & Sea