BOEEP's Stainless Steel 304 316 Sewage Treatment Plant STP SBR System Rotary Rotating Revolving Decanter Tank Model XBS guarantees dependable and efficient sewage treatment in domestic areas, facilities, and commercial settings. This top-notch product was designed with superior materials, making certain it can withstand even the most challenging conditions.

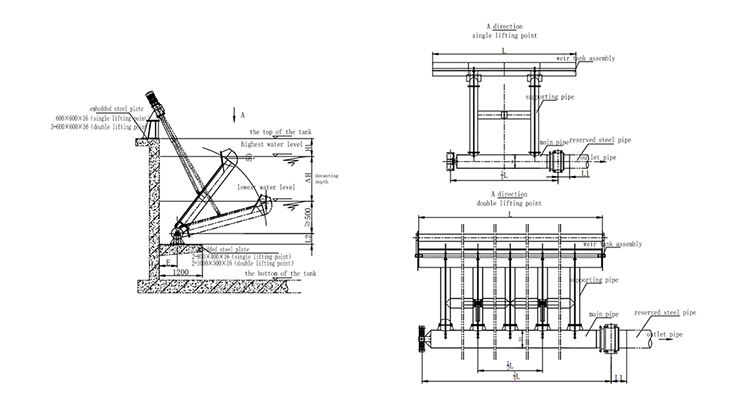

Keeping the maximum requirements in sewage treatment plants, BOEEP's model XBS uses the Sequential Batch Reactor (SBR) process of wastewater treatment. This process, utilizing the rotating, revolving decanter tank technology, really helps to make certain that all wastewater is effortlessly addressed in batches.

Among the list of outstanding options that come with this STP SBR System is the higher level rotary technology. This advanced level guarantees superior treatment by increasing contact between wastewater and the medium treatment. Furthermore, this technology guarantees treatment, reducing the chance of untreated wastewater.

The decanter tank system in the BOEEP STP SBR System is perfect for maximum effectiveness. The revolving feature of the tank ensures the circulation of wastewater inside the treatment medium, increasing the effectiveness with this SBR procedure. The rotating system decreases the chance of sludge build-up, ensuring effortless and efficient procedure.

The Stainless Steel 304 316 construction of this specific sewage treatment plant guarantees lasting durability. This top-notch product is famous because of its capability to withstand even the most challenging of surroundings, making the STP SBR System a great choice for every commercial procedure.

Also, the XBS model is produced with effectiveness in mind. The device is automatic, making sure wastewater is addressed constantly with just minimal manual intervention. The automated unit is also energy-efficient, reducing electricity expenses and minimizing environmentally friendly effect of wastewater treatment procedures.

The BOEEP’s Stainless Steel 304 316 Sewage Treatment Plant STP SBR System Rotary Rotating Revolving Decanter Tank Model XBS is the perfect solution for wastewater treatment. The advanced level process with the rotating, revolving decanting tank technology guarantees dependable, efficient, and durable wastewater treatment. The top-notch materials, advanced level technology, and energy-efficient design makes this product a top option for any commercial or wastewater treatment procedure

Model |

Capacity - m³/hr |

Load of water flow - L/ms |

L - m |

L1 - mm |

L2 - mm |

DN - mm |

△H - mm) |

E - mm |

||||||

XBS300 |

300 |

20-40 |

4 |

600 |

250 |

300 |

1.0

1.5

2.0

2.5

3.0

|

500 |

||||||

XBS400 |

400 |

5 |

||||||||||||

XBS500 |

500 |

6 |

300 |

400 |

||||||||||

XBS600 |

600 |

7 |

||||||||||||

XBS700 |

700 |

9 |

800 |

350 |

700 |

|||||||||

XBS800 |

800 |

10 |

500 |

|||||||||||

XBS1000 |

1000 |

12 |

400 |

|||||||||||

XBS1200 |

1200 |

14 |

||||||||||||

XBS1400 |

1400 |

16 |

500 |

600 |

||||||||||

XBS1500 |

1500 |

17 |

||||||||||||

XBS1600 |

1600 |

18 |

||||||||||||

XBS1800 |

1800 |

20 |

600 |

650 |

||||||||||

XBS2000 |

2000 |

22 |

700 |

Q: Are you trading company or manufacture

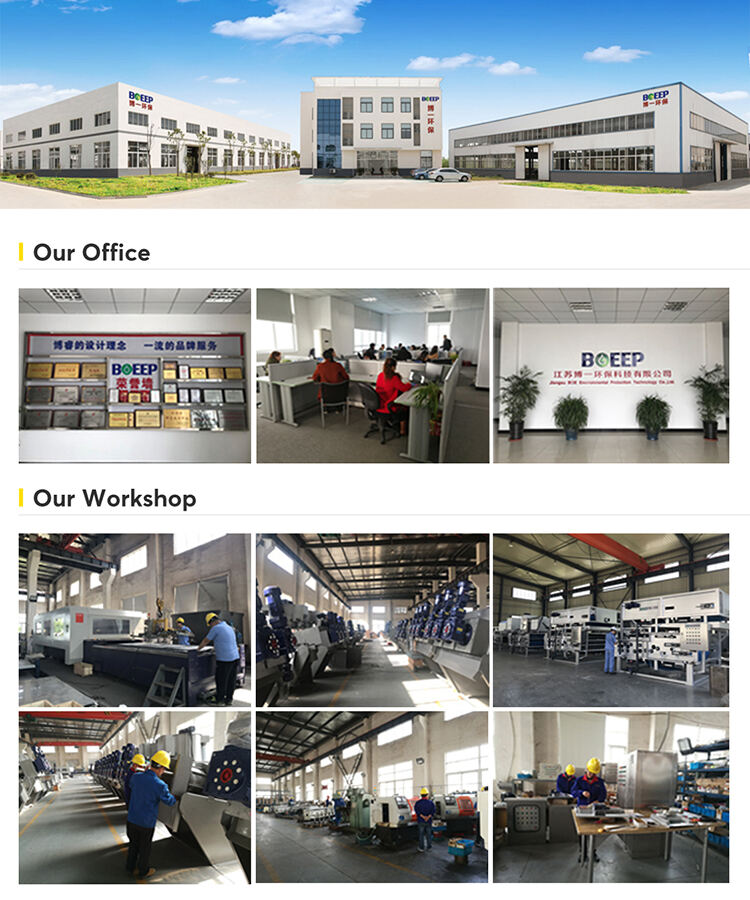

A: We are both manufacture and trading company. We have over 20 years' professional experience as a waste water treatment equipment manufacturer and engineering service enterprise

Q: Where is your factory located

A: Yangzhou City, which is very close to Shanghai with only less than 3 hours' driving

Q: Do you provide OEM service

A: Yes. Any required logos is available

Q: How about the production capacity of your company

A: Our factory covers area over 20,000M2 and produces machines 2000 sets per year

Q: How could we trust you and your company? This is first time transaction

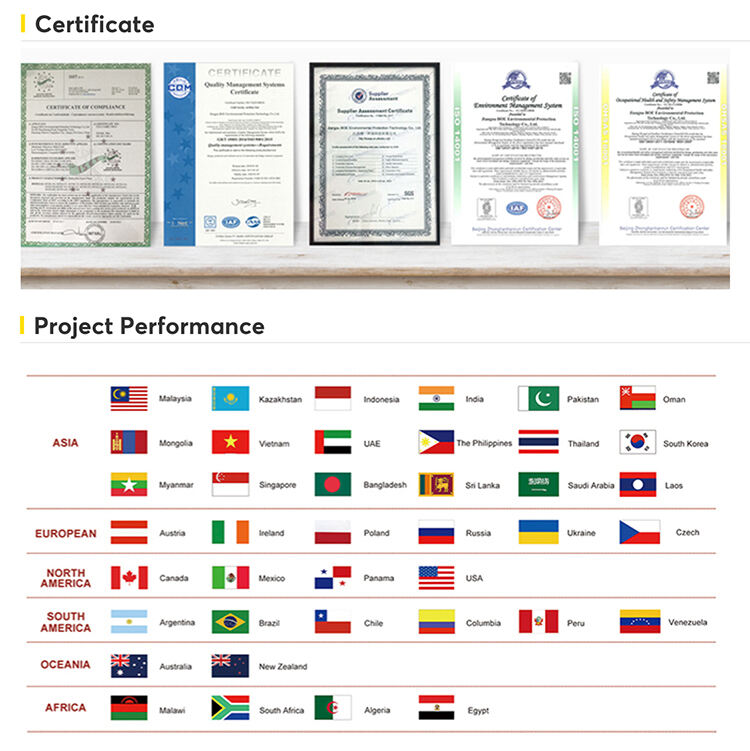

A: Our company has more than 20 years professional experience. We cooperate over 1000 customers in China and overseas. We export nearly 40 countries all over the world. Welcome to our company and watch our plant production condition any time

Q: What certificates do you have

A: CE/ISO/SGS

Q: Do you offer after-sales service

A: Yes. Engineers available

Q: How long is your warranty

A: One year after the arrival of the goods. During this period, as long as it is not a man-made damage, we send the damaged parts free of charge

Q: What about your delivery time

A: Normally within 45 days against down payment

Q: What about the package of your export product

A: We use anti-corrosion wooden case with foam inside

Q: What kind of payment do you accept

A: T/T, L/C, PAYPAL, Cash, D/P, D/A, WESTERN UNIION, MONEYGRAM

Q: What kind of transportation do you offer

A: Customers decide freight mode, Air, Land & Sea