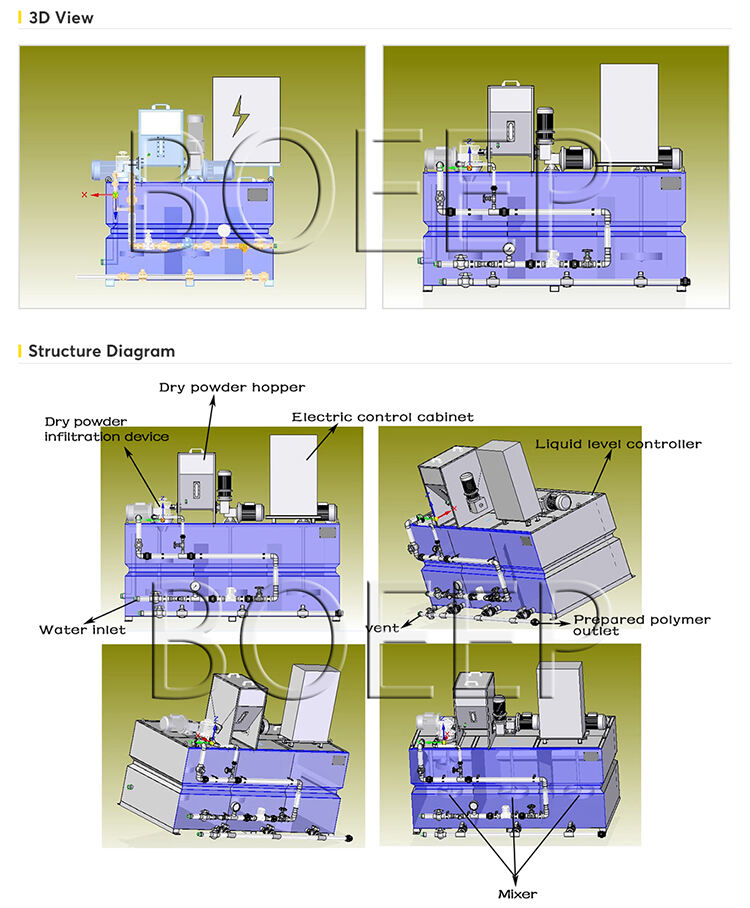

BOEEP's Water Treatment Chemical Dosing System is a revolutionary, automated polymer dosing machine and filling product that was made to meet up with the requirements of waste water treatment plants. This method makes usage of advanced technology that offer accurate and efficient dosing of chemical compounds for water treatment.

The machine would work for dosing many different chemicals utilized in wastewater treatment, including polymers, coagulants, and Flocculants. The automated polymer dosing machine guarantees an exact dosage need for chemical, reducing the chance of mistakes and ensuring constant quality. The device is simple to work and keep maintaining, making it a perfect solution to waste water treatment plants of every size.

The BOEEP’s Water Treatment Chemical Dosing System also includes a filling device which guarantees a continuing availability of chemical substances to your dosing device. This has a high-capacity system tank to keep chemical substances, decreasing the necessity for constant refilling. The filling product comes with automated shut-off valves in order to prevent overfilling, ensuring safe procedure.

The device is wholly automatic, which improves effectiveness and decreases work expenses. It can be effortlessly built-into your current waste water plants, making this an economical solution to organizations seeking to enhance their wastewater treatment procedures. The automated polymer machines can be programmed to dose chemical substances at particular times, minimizing the need for manual monitoring and intervention.

The BOEEP’s Water Treatment Chemical Dosing is extremely customizable. It can be tailored to your specific requirements of the wastewater treatment plant, enabling accurate dosing of compounds and optimal gratification. This freedom makes it to be a perfect solution for waste water treatment plants with specific needs.

The device was also built to be eco-friendly. The automated polymer machine implies that the right amount of chemical compounds is put in the wastewater, reducing waste and minimizing the effect in the environment. The high-capacity tank in the stuffing product also decreases the need for regular chemical deliveries, further minimizing the ecological effect.

The BOEEP’s Water Treatment Chemical Dosing System is a dependable and efficient solution in wastewater treatment plants. Its automated polymer dosing device and accurate filling device dosing of chemical compounds, while its modification choices makes it adaptable to almost any plant's requirements. The unit is eco-friendly, making it an excellent option to very organizations that wants to cut back their ecological effect. The BOEEP’s Water Treatment Chemical Dosing System is an ideal item to every wastewater treatment plants with its power and flexibility

Model |

YT-500 |

YTH-1000 |

YTH-1500 |

YTH-2000 |

YTH-2500 |

YTH-3000 |

YTH-4000 |

YTH-5000 |

YTH-6000 |

Capacity - L/h |

500 |

1000 |

1500 |

2000 |

2500 |

3000 |

4000 |

5000 |

6000 |

Power - kw |

1.7 |

2.45 |

2.45 |

2.45 |

3.5 |

3.9 |

3.9 |

3.9 |

3.9 |

Powder dosage - kg/h |

1-5 |

2-10 |

2-10 |

3-15 |

3-15 |

3.5-20 |

3.5-20 |

3.5-20 |

3.5-20 |

Water inlet flow - m3/h |

0-1.3 |

0-2.6 |

0-2.6 |

0-2.6 |

0-4.5 |

0-4.5 |

0-4.5 |

2.4-14 |

2.4-16 |

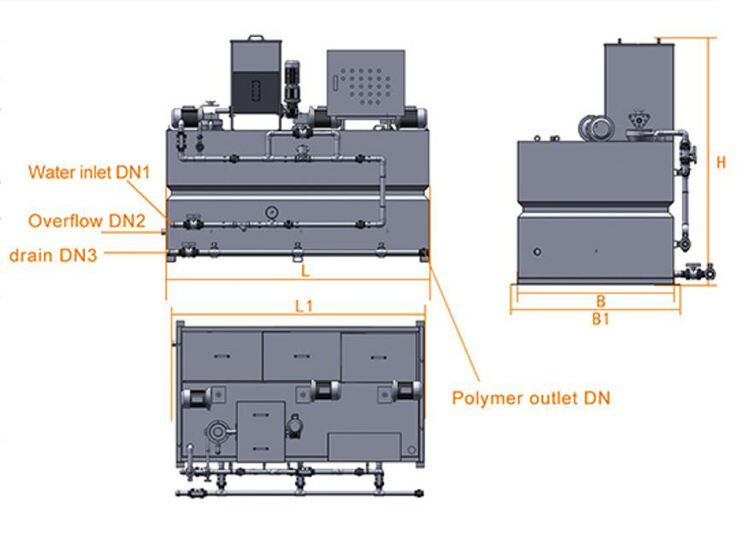

L - mm |

1370 |

2000 |

2130 |

2200 |

2400 |

2400 |

2720 |

3250 |

3400 |

B - mm |

680 |

1000 |

1070 |

1200 |

1200 |

1300 |

1400 |

1650 |

1650 |

H - mm |

1500 |

1710 |

1710 |

1900 |

2140 |

2180 |

2250 |

2250 |

2250 |

L1 - mm |

1300 |

1930 |

2060 |

2130 |

2330 |

2330 |

2650 |

3170 |

3320 |

B1 - mm |

730 |

1050 |

1120 |

1250 |

1250 |

1350 |

1450 |

1750 |

1750 |

Powder outlet DN |

DN25 |

DN32 |

DN32 |

DN32 |

DN40 |

DN40 |

DN40 |

DN40 |

DN50 |

Water inlet DN1 |

DN25 |

DN32 |

DN32 |

DN32 |

DN40 |

DN40 |

DN40 |

DN40 |

DN50 |

Overflow DN2 |

DN32 |

DN40 |

DN40 |

DN40 |

DN40 |

DN50 |

DN50 |

DN50 |

DN50 |

Drain DN3 |

DN25 |

DN32 |

DN32 |

DN32 |

DN40 |

DN40 |

DN40 |

DN40 |

DN50 |

Net weight - kg |

250 |

400 |

490 |

550 |

650 |

700 |

770 |

1160 |

1200 |

Q: Are you trading company or manufacture

A: We are both manufacture and trading company. We have over 20 years' professional experience as a waste water treatment equipment manufacturer and engineering service enterprise.

Q: Where is your factory located

A: Yangzhou City, which is very close to Shanghai with only less than 3 hours' driving

Q: Do you provide OEM service

A: Yes. Any required logos is available

Q: How about the production capacity of your company

A: Our factory covers area over 20,000M2 and produces machines 2000 sets per year

Q: How could we trust you and your company? This is first time transaction

A: Our company has more than 20 years professional experience. We cooperate over 1000 customers in China and overseas. We export nearly 40 countries all over the world. Welcome to our company and watch our plant production condition any time

Q: What certificates do you have

A: CE/ISO/SGS

Q: Do you offer after-sales service

A: Yes. Engineers available

Q: How long is your warranty

A: One year after the arrival of the goods. During this period, as long as it is not a man-made damage, we send the damaged parts free of charge

Q: What about your delivery time

A: Normally within 45 days against down payment

Q: What about the package of your export product

A: We use anti-corrosion wooden case with foam inside

Q: What kind of payment do you accept

A: T/T, L/C, PAYPAL, Cash, D/P, D/A, WESTERN UNIION, MONEYGRAM

Q: What kind of transportation do you offer

A: Customers decide freight mode, Air, Land & Sea