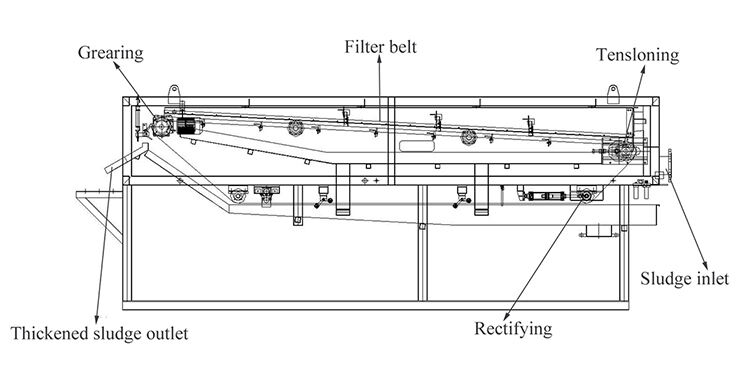

BOEEP’s Automatic stainless steel industrial filtering equipment sludge gravity thickener thickening belt filter press is a revolutionary and efficient solution for industrial wastewater treatment. Designed to address high volumes of sludge, this item provides dependable and minimal procedure.

The automated stainless design in this purification equipment is perfect for durability, having a corrosion-resistant outside that has the capacity of withstanding perhaps the harshest chemical surroundings. Built with a thickening belt filter press, the equipment can effortlessly eliminate solid particles from wastewater, ensuring clean effluent release and minimal ecological effect.

Having its advanced sludge gravity technology, BOEEP’s filtering equipment simplifies the purification procedure and increases effectiveness. The functional automation of this system is effortless in monitoring and controlling the purification procedure, reducing the necessity for manual intervention. And also, this allows you to reduce the likelihood of operator mistake, ensuring constant and dependable gratification.

This commercial filtering equipment is great for applications such as food and drink processing, petrochemicals, beauty and personal maintenance systems, and lots of other programs that induce high volumes of wastewater. BOEEP’s sludge gravity thickener thickening belt filter press can handle an array of sludge kinds, including municipal wastewater, commercial effluent, and biogas residue

This was made with security features to guard operators and minimize the possibility of accidents in addition to its durability and effectiveness. The product is very easy to put in and run, with easy guidelines and low maintenance.

With BOEEP’s Automatic stainless steel industrial filtering equipment sludge gravity thickener thickening belt filter press, industrial plant supervisors can rely upon the effectiveness and dependability of their wastewater treatment procedure. This system is well known for the top-quality construction, efficient performance, and flexibility, which makes it a higher choice for different applications. Whether you want to improve the potency of an individual's wastewater treatment procedure or guarantee conformity with ecological laws, BOEEP’s industrial filtering equipment is the right option

Model |

DN1.0 |

DN1.5 |

DN2.0 |

DN2.5 |

Remark |

|||

Belt width - mm |

1000 |

1500 |

2000 |

2500 |

||||

Capacity(m3/h) Inlet concentration - S.S. 0.2-1.0%

|

20-40 |

40-60 |

60-80 |

80-100 |

Depending on the characteristic of sludge |

|||

Sludge cake moisture content - % |

90-96 |

90-96 |

90-96 |

90-96 |

||||

Motor power - kw |

Driving motor frequency control |

0.75 |

1.5 |

2.2 |

3.0 |

|||

Agitator motor |

0.75 |

0.75 |

1.1 |

1.1 |

||||

Lower collecting tray for filtrate |

YES |

YES |

YES |

YES |

||||

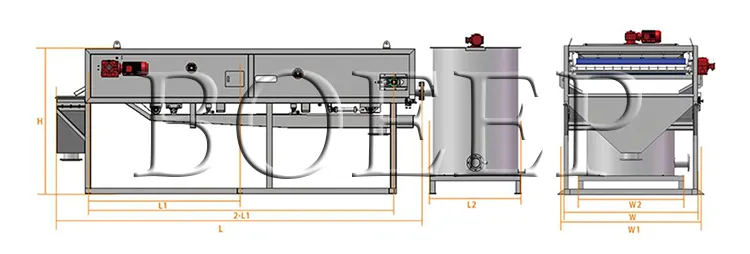

External dimension - mm |

L |

3900 |

4900 |

5900 |

6500 |

Please ask for the actual installation size drawing before purchasing |

||

W |

1785 |

2285 |

2785 |

3285 |

||||

H |

2085 |

2085 |

2085 |

2085 |

||||

L1 |

1600 |

2100 |

2600 |

3050 |

||||

L2 |

1200 |

1600 |

2000 |

2500 |

||||

W1 |

1885 |

2385 |

2885 |

3385 |

||||

W2 |

1200 |

1700 |

2100 |

2600 |

||||

Reference weight - kg |

1100 |

1450 |

1850 |

2350 |

||||

Q: Are you trading company or manufacture

A: We are both manufacture and trading company. We have over 20 years' professional experience as a waste water treatment equipment manufacturer and engineering service enterprise

Q: Where is your factory located

A: Yangzhou City, which is very close to Shanghai with only less than 3 hours' driving

Q: Do you provide OEM service

A: Yes. Any required logos is available

Q: How about the production capacity of your company

A: Our factory covers area over 20,000M2 and produces machines 2000 sets per year

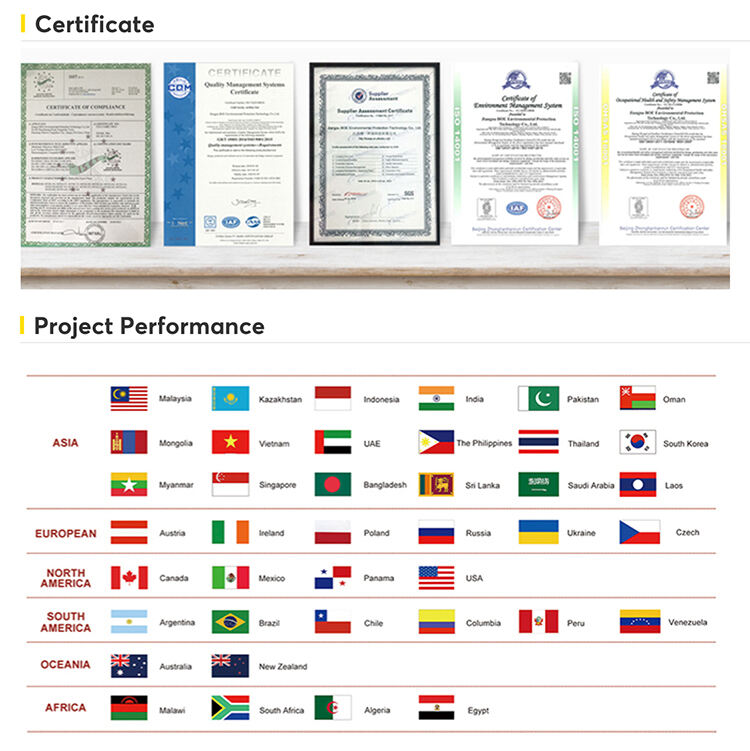

Q: How could we trust you and your company? This is first time transaction

A: Our company has more than 20 years professional experience. We cooperate over 1000 customers in China and overseas. We export nearly 40 countries all over the world. Welcome to our company and watch our plant production condition any time

Q: What certificates do you have

A: CE/ISO/SGS

Q: Do you offer after-sales service

A: Yes. Engineers available

Q: How long is your warranty

A: One year after the arrival of the goods. During this period, as long as it is not a man-made damage, we send the damaged parts free of charge

Q: What about your delivery time

A: Normally within 45 days against down payment

Q: What about the package of your export product

A: We use anti-corrosion wooden case with foam inside

Q: What kind of payment do you accept

A: T/T, L/C, PAYPAL, Cash, D/P, D/A, WESTERN UNIION, MONEYGRAM

Q: What kind of transportation do you offer

A: Customers decide freight mode, Air, Land & Sea