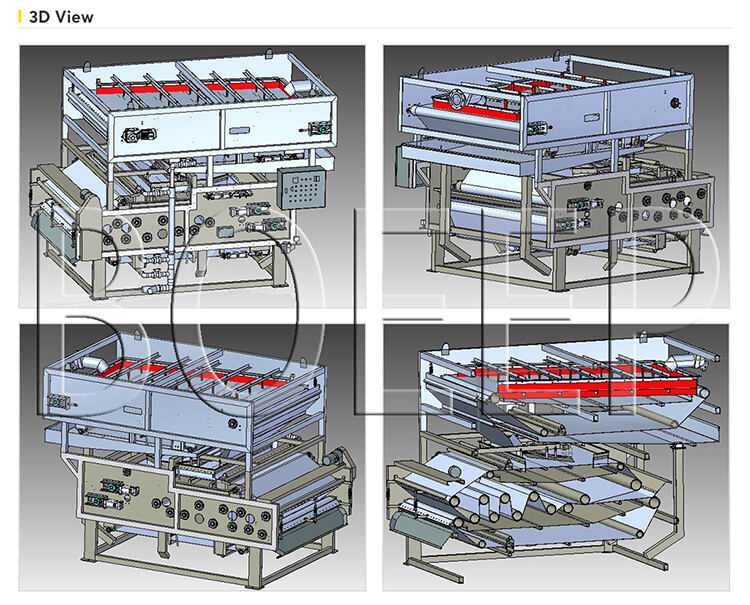

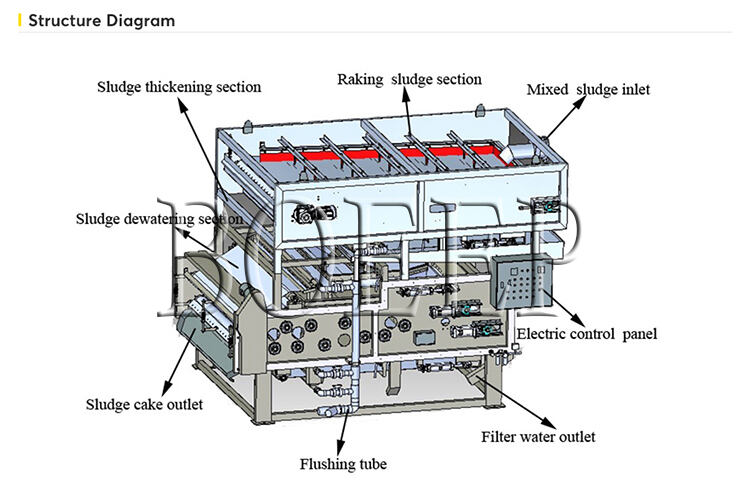

If you're searching for a dependable, efficient solution to get rid of tannery waste water, look no further than BOEEP’s Tannery Waste Water Treatment Plant Belt Filter Press Equipment. This advanced sludge de-watering system has a cutting-edge technology to rapidly process waste water and minimize the amount and weight of the sludge.

The BOEEP’s Tannery Waste Water Treatment Plant Belt Filter Press Equipment consists of durable, top-quality materials, including SS304 and 316 stainless steel, ensuring a lengthy solution life and opposition to corrosion, rusting, as well as other types of harm. The equipment filter press technology employed by this system permits constant, automated procedure, reducing the necessity for human intervention and minimizing downtime.

The screen of this is user-friendly and simple to navigate. The equipment was built to be an easy task to use, with minimal upkeep needs and paid down gas consumption. In addition, the BOEEP’s Tannery Waste Water Treatment Plant Belt Filter Press Equipment is green, consuming less power and emitting less toxins than conventional waste water processing practices.

Among the key attributes of this is its impressive sludge de-watering ability. This is dense, hefty, and tough to handle. The BOEEP’s Tannery Waste Water Treatment Plant Belt Filter Press Equipment takes this sludge and extracts dampness, reducing its weight and amount and making it simpler to care for and dump.

The BOEEP’s Tannery Waste Water Treatment Plant Belt Filter Press Equipment is an outstanding investment to any tannery wanting to optimize its waste water treatment procedure. This cutting-edge system will reduce power usage, minimizing maintenance, and increasing sludge de-watering. Contact BOEEP to master more of this item and understand how it will help your operations today

BOEEP sludge dewatering belt press machine is mainly used for processing the sludge which is not concentrated in the thickening pool, such as A/O residual sludge or SBR residual sludge. It has two functions: concentrating and dewatering. Compared with Rotary Drum Thickening Belt Filter Press the structure is different, for the sludge is thickened by the gravity, which is used in the higher capacity

It runs smoothly and normally, no impact, vibration and abnormal sound, after all parts are checked to be qualified, the assembly can be executed. In order to adjust frame horizontal conveniently, Frame is fixed on the foundation with anchor bolts, and equipping with adjusting device

Model |

DNY1.0 |

DNY1.5 |

DNY2.0 |

Remark |

|||

Belt width - mm |

1000 |

1500 |

2000 |

||||

Capacity(3/h), inlet concentration - S.S.0.8-1.5% |

6-12 |

10-18 |

15-25 |

Depending on the characteristic of sludge |

|||

Sludge moisture content - % |

75-85 |

75-85 |

75-85 |

||||

Motor power - kw |

Driving motor frequency control |

0.37 |

0.75 |

0.75 |

|||

Belt thickening motor frequency control |

0.75 |

0.75 |

1.1 |

||||

Agitator motor |

0.37 |

0.75 |

0.75 |

||||

Lower collecting tray for filtrate |

YES |

YES |

YES |

||||

External dimension - mm |

L |

4080 |

4770 |

5270 |

Please ask for the actual installation size drawing before purchasing |

||

W |

1780 |

2135 |

2770 |

||||

H |

2680 |

2410 |

2910 |

||||

Base dimension L1*W1 - mm |

2110*1336 |

2440*1720 |

2715*2420 |

||||

Base dimension L2*W2 - mm |

710*710 |

790*790 |

700*700 |

||||

Reference weight - kg |

1600 |

2470 |

4130 |

||||

Q: Are you trading company or manufacture

A: We are both manufacture and trading company. We have over 20 years' professional experience as a waste water treatment equipment manufacturer and engineering service enterprise

Q: Where is your factory located

A: Yangzhou City, which is very close to Shanghai with only less than 3 hours' driving

Q: Do you provide OEM service

A: Yes. Any required logos is available

Q: How about the production capacity of your company

A: Our factory covers area over 20,000M2 and produces machines 2000 sets per year

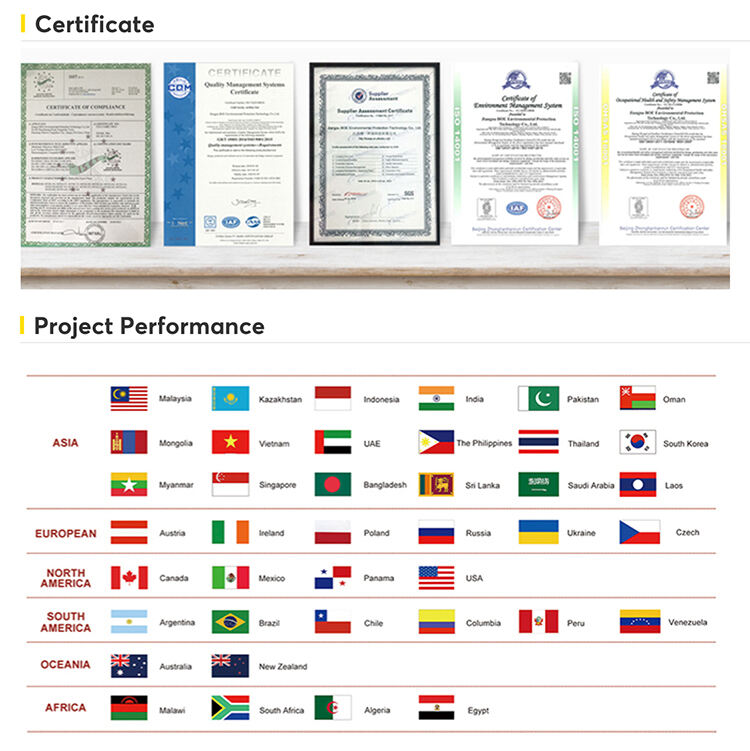

Q: How could we trust you and your company? This is first time transaction

A: Our company has more than 20 years professional experience. We cooperate over 1000 customers in China and overseas. We export nearly 40 countries all over the world. Welcome to our company and watch our plant production condition any time

Q: What certificates do you have

A: CE/ISO/SGS

Q: Do you offer after-sales service

A: Yes. Engineers available

Q: How long is your warranty

A: One year after the arrival of the goods. During this period, as long as it is not a man-made damage, we send the damaged parts free of charge

Q: What about your delivery time

A: Normally within 45 days against down payment

Q: What about the package of your export product

A: We use anti-corrosion wooden case with foam inside

Q: What kind of payment do you accept

A: T/T, L/C, PAYPAL, Cash, D/P, D/A, WESTERN UNIION, MONEYGRAM

Q: What kind of transportation do you offer

A: Customers decide freight mode, Air, Land & Sea